Within the architectural, engineering & construction (AEC) industry, we are witnessing the rapid advancement of the technology within building information modeling (BIM) and its use in managing buildings and facilities post construction. One of the most powerful tools that has emerged in the last few years is the “digital twin”, which is essentially a virtual replica of a building or facility, that exists in the digital realm. As technology advances, it’s becoming increasingly evident that the digital counterpart can evolve from a static model into a dynamic, real-time simulation that can mirror the real-world performance of the building or facility. Utilizing this tool can enable facility management (FM) teams to monitor, assess and maintain their facilities to an automated level, never seen before.

For example:

- Within data centers, digital twins can track temperature variations and power usage across server racks allowing personnel to react to equipment breakdowns and emergencies much faster.

- On university campuses with multiple buildings, maintenance work orders and spare component inventories historically managed through a variety of computerized maintenance management systems (CMMS) can be tied to the digital twin for management within a centralized location rather than being spread across multiple platforms.

- Within hospitals’ central utility plants, routine maintenance of chillers and other equipment can be recorded and stored within the digital twin platform to ensure maintenance is performed on schedule, so the life of equipment is extending to the fullest possible.

Part of the Process – Do the Talking First

Building the digital twin begins early in the design phase when MEP engineers work with owners and end users to identify “assets” to be managed within the twin. Assets are physical items in the building or facility that the owners or end users deem essential to be managed, maintained or routinely replaced throughout the life of the building. Assets could be items as large as an emergency electrical generator, or as small as the electrical outlet served by that generator.

Many facilities have current asset management plans in place, and we assist them by bringing all of their platforms together onto one single platform. In cases where facilities do not have these plans in place, we start the process from the ground up. When we engage in these discussions, it’s important to manage the expectations of users and clients’ wants and needs. We sometimes find that the “wants” exceed the budget of a project and in such situations we need to help clients identify a more realistic asset list. Part of our responsibility is to help them balance what’s important for their FM programs with budgetary limitations.

Part of the Process – Getting the Right Pieces in the Right Places

Once assets have been identified and the project is underway, the next step is to study the architect’s and engineer’s design models or contractor’s as-built models. We pare down these down to the essentials by removing extraneous objects that are not assets.

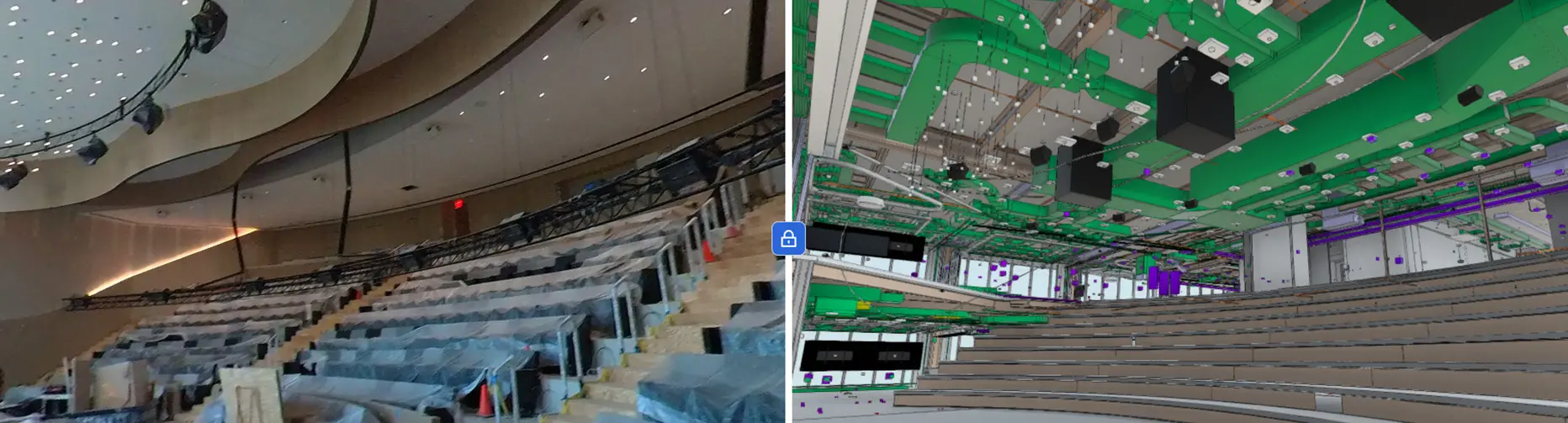

The actual development of the twin within the BIM platform can run in tandem with construction or can be done post construction. Regardless of this timeline, it is essential to have a reality capture of the space to ensure accuracy of where assets are located within the model. This is typically done by laser scan and converted to a point cloud to be incorporated into the model.

Part of the Process – Testing…Testing …Testing 1, 2, 3

After the twin is built and all parties have consensus that the designated assets are included, testing by the end user should be performed to verify accuracy and performance. During this period, we should work alongside the end users to refine and tweak the model so the final fully functioning product can be completely turned over to the client for its use.

The Value Proposition

As we are working so closely with owners and end users during the process, we are building not only a digital twin but also relationships. It is essential that we truly listen to clients’ needs and help manage their expectations to deliver a final product that works properly to manage their facilities long term. This helps to solidify us as trusted long-term partners. The value proposition of the digital twin itself has many facets, but one of the most notable is the transfer of knowledge. In a time where the knowledge of a generation is being lost due to retirements, it is critical for new employees within FM groups to quickly learn their facilities inside and out. Having a virtual twin within a digital platform can assist in this education.

Conclusion

The promise of digital twins lies within the ability to completely mirror a real-life facility or building on a digital platform. Whether to monitor statically or to control processes and simulations, this technology will allow future generations to maintain facilities more efficiently and predictably. As technology will advance at a rapid rate, and more possibilities arise, we must stay abreast of these developments so that we can continue to be entrusted guides into the boundless future that lies ahead.